Commonly used type of suspended slabs for low rise buildings up to date would still be the conventional method of one way, two way and composite slabs (with steel decking).

Depending on your region perhaps may have heard about the use of precast slabs directly done from manufacturing plants with proper curing periods and for some high-rise buildings already using post tension slabs.

Quite a common practice for designers/students alike to determine if one way or two way slab by simply getting the ratio between the longer span and the shorter span with the given ratio formula below.

But others would argue that it depends on how the slab will bend when subjected to a given load on which direction is more dominant regardless of being supported on both sides or on all sides or even classified as one-way or two-way.

Nonetheless, holding a piece of notebook or paper either on short or long span will give you already an idea which direction is more prone to deflection when not properly supported on the other sides.

where :

L is the longer span

S for the shorter span

one way if (greater or equal to 2)

L/S>2

two way if (less than 2)

L/S<2

Two governing bars as you should always remember when dealing with any concreting works which is your Main bars and Temp bars(also known as Distribution bars).

Once you determine which of type of slab, regardless of its type you must always remember that the main bars should always run parallel to your shorter span and always located at the bottom.

This way your main bars running along the short span (parallel) would support your beams (@ long span) that carries the weight of the slab.

Imagine your hands like from image below being parallel to the shorter span will give more resistance than having it placed perpendicular along short span.

Main bars spacing

max spacing in slab

★ not more than 3D or 300mm (while other codes 3t or 450mm)

★ where D is effective depth of slab

Temp (Distribution) bars spacing

max spacing of temp bars in slab

★ not more than 5D or 450mm

★ where D is effective depth of slab

source: link

Max diameter of bar

★ should not exceed 1/8th of slab thickness

∴ slab thickness 100mm

= 100/8

= 12.5mm Ø or ✔12mm Ø

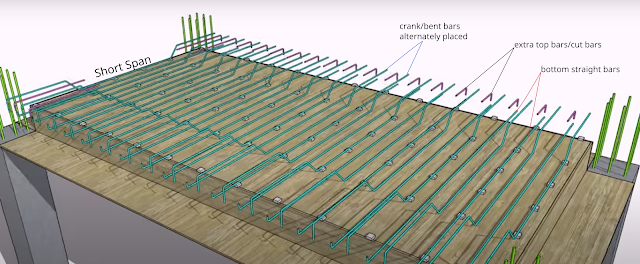

A sample overview how your one way slab rebar layout should look like

|

| credits_3d_animation_watch_ here |

ONE WAY SLAB REBAR ESTIMATE

Sample Computation:

➤ Say you have 2m x 6m slab (say supported on all corners)

➤ 12mm Ø main bar spacing @ 0.20m o.c.

➤ 10mm Ø temp bars @ 0.20m o.c.

➤ 125mm slab thickness

a. Checking for type of slab (as general practice)

∴ 6m/2m = 3m greater than 2 then ✔one way

Main bars parallel to Short span

● others deduct concrete cover on both sides (optional)

● total length/spacing = pcs + 1

= 6m/0.20

= 30 + 1

= ✔ 31 pcs (take note that half will be for your cranked bars)

say 15pcs crank/bent and the rest for bottom straight bars (16pcs).

will be alternately placed with one straight bottom bar to be followed by a crank/bent bar.

Extra or cut bars

● don't forget those cut bars above your bottom straight bars

say 16pcs x 2 sides

=✔ 32 pcs (cut size will be smaller)

total of 31pcs straight/crank bars

total of 32pcs extra/cut bars (cut size is shorter)

Temp bars parallel to Long span

● others deduct concrete cover on both sides (optional)

● total length/spacing = pcs + 1

= 2m/0.20

= 10 + 1

= ✔ 11 pcs

note for the top layer temperate bars along L/4 of your 'short span'

= 2m/4

=0.50/0.20

=2.5 + 1

=3.5 pcs say ✔4pcs x 2 for the other side

=✔ 8pcs

total of 19pcs temp bars

Once you're done with the number of pcs per span, let's proceed to compute for possible cut size of rebars.

c. Cut size for bars

Main bars parallel to Short span

● others add 40d for Ld on both sides (optional since we are taking it at center to center of beams)

● total length + 2(bend) + 2(hook) for bent/crank bars

● total length + 2(hook) for straight bars

➤ total length + 2(0.42dc) + 2(16d) for crank/bent up bars

dc as the depth of the crank bar or bent (instead of writing as d so you won't get confused with the other d in 16d which is for the diameter of the bar)

where:

dc=thickness of slab - 2(concrete cover) - d(bar diameter)

concrete cover @ 20mm (0.02m)

solving for dc:

0.125 - 2(0.02) - 0.012 = 0.073m

substitute in 0.42dc

= 2m + 2(0.42 x 0.073) + 2(16 x 0.012)

= 2.445m say 2.45m length for ✔ bent/crank bars

= 2m + 2(16 x 0.012)

= 2.38m say 2.40m length for ✔ straight bars

Extra or cut bars

● L/4 + 1(hook)

= 2m/4 + 1(16 x 0.012)

= 0.692m say 0.70m length for the ✔ extra/cut bars

Temp bars parallel to Long span

● others add 40d for Ld on both sides (optional since length taken from center to center of beams)

● total length + 2(hook)

= 6m + 2(16 x 0.01)

= 6.32m say 6.35m length for ✔ temp bars

For the final part after getting the possible cut size of rebars let's proceed to the number of pcs to be ordered from nearest hardware/suppliers.

d. Number of steel bars needed

❖ trying at 6m length for main bars (crank and straight bars)

6m/2.45m=2.45 say 2pcs only usable

● 15pcs/2 = 7.5 pcs or say ✔ 8pcs-12mm Ø x 6m length (for crank/bent)

6m/2.40m=2.5 say 2pcs only usable

● 16pcs/2 = ✔ 8pcs-12mm Ø x 6m length (for straight)

6m/0.70m=8.5 say 8pcs only usable

● 32pcs/8 = ✔ 4pcs-12mm Ø x 6m length (for extra/cut)

total:

✔ 20pcs-12mm Ø x 6m length for our Main Bars

❖ trying at 7.5m length for temp bars

7.5m/6.35m=1.18 say 1pc only usable

19pcs/1 = ✔ 19pcs 10mm Ø x 7.5m length

total:

✔ 19pcs-10mm Ø x 7.5m length for our Temp Bars

e. Tie Wire needed

31 x 11 x 0.30m = 102.30

= 102.30/53

= ✔ 1.93kgs #16 G.i. wire

add also for the temp bars & cut bars joints above

4 x 16 x 0.30m x 2 sides = 38.40

= 38.40/53

= ✔ 0.724kgs #16 G.i. wire

total:

✔ 2.654kgs say 2.65kgs #16 G.i. wire

Weight of Steel Bar

If you wish to convert also your steel bar pcs to kgs always remember

d2/162 = kgs/m (you may also refer to table in this post)

Ø (diameter of bar)2 /162 = kgs/m

✔ 20pcs-12mm Ø x 6m main bars

((12mm)2 /162) x 6m length x 20pcs = 105.6kgs say 106kgs

✔ 19pcs-10mm Ø x 7.5m temp bars

((10mm)2 /162) x 7.5m length x 19pcs = 87.96kgs say 88kgs

Feel free to add up pcs or kgs once you made your estimates and later on can get the ratio in terms of per sqm or per cu.m when making concrete works estimates.

Here's what we mean of getting the ratio so you won't spend much time calculating per piece if you are trying to come up with a quick estimate per area or per volume.

Let's derive per cu.m using above estimated materials

Volume Method

Just a quick sample in cu.m

volume of slab = 2m x 6m x 0.125m

= ✔ 1.50cu.m

getting the kgs of steel bars per 1 cu.m

106 kgs/1.50cu.m = 70.6kgs say ✔ 75kgs of 12mm Ø per cu.m

88 kgs/1.50cu.m = 58.6kgs say ✔ 65kgs of 10mm Ø per cu.m

if you may ask how to get number of pcs of 12mm Ø out of the kgs unit?

★ just reverse the process we made earlier when converting pcs to kgs

=75kgs / (122 /162) / steel length desired

=75 /0.888 /6

=14pcs per cu.m using 12mm Ø x 6m length

=65kgs / (102 /162) / steel length desired

=65 /0.617 /7.5

=14pcs per cu.m using 10mm Ø x 7.5m length

if you wish a different length then substitute with the length in mind to get the number of pcs.

countercheck 14pcs/cu.m x 1.50cu.m = ✔ 21pcs almost near from computed 20pcs earlier

so when given a problem of one way slab say 3m x 5m x 0.125 = 1.875cu.m or sometimes your client will just mention the volume of slab?

then you can simply compute for the number of kgs or pcs real quick

75kgs/cu.m x 1.875cu.m = ✔ 140.6kgs say 145kgs of 12mm Ø

or via pcs

14pcs/cu.m x 1.875cu.m = 26.25pcs say 27pcs of 12mm x 6m length

You can do the same steps for Tie wire to get the kgs per cu.m or try to practice getting the number of pcs or kgs per square meter to have more options.

You may refer to this table to add those bend on your cranked bars, length from table is already for both sides.

| Bend Size (from 0.42D) |

| Thickness of Slab | Added bend length |

| 4" | 50mm |

| 5" | 70mm |

| 6" | 90mm |

| regardless of bar diameter of 10mm or 12mm |

source: link

A quick check:

say slab of 125mm with 12mm Ø 25mm concrete cover

=125-2(25)-12

=63mm

=0.42 x 63mm

=26.46 x 2 sides

=52.92mm say ✔ 53mm added bend length (from table is more than enough)

say slab of 125mm with 10mm Ø 20mm concrete cover

=125-2(20)-10

=75mm

=0.42 x 75mm

=31.50 x 2 sides

=✔ 63mm added bend length (from table is more than enough)

Now that you get the idea on how to get estimate for your rebars, you may now proceed to two way slab and see the difference here.

Lastly once you master your steel bars, time to make it to the next level and start on concrete works here.

Hope this guide will save you time when making your estimates in the future, good luck!

Share with friends if you find this helpful. Thanks!

CONCRETE SLAB (One Way Slab)

Reviewed by b.o.m.

on

9:12 PM

Rating:

Reviewed by b.o.m.

on

9:12 PM

Rating:

Reviewed by b.o.m.

on

9:12 PM

Rating:

Reviewed by b.o.m.

on

9:12 PM

Rating:

No comments: